HIGH PRODUCTION

CAST IRON

HOLEMAKING

Hi-PerCarb® | Series 141K

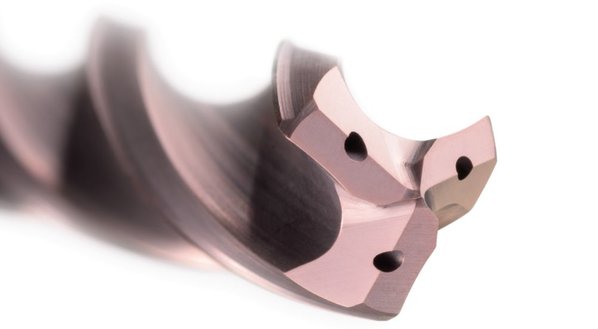

The Series 141K Drill highlights a Tri-Margin Design that significantly enhances hole stability, surface finish, roundness, cylindricity, and hole size control compared to two-flute designs. Additionally, the drill incorporates edge and corner protection for reduced breakout, an automated edge treatment process to extend tool life, and a minimal margin design to minimize frictional heat and maintain consistent contact width during use.

Features

HIGH PERFORMANCE TRI-MARGIN DESIGN

- Improved hole stability over two-flute designs

- Superior surface finish, roundness, and hole cylindricity

SELF-STABILIZING POINT

- Pyramid design stabilizes the drill on contact with the workpiece

- Automated edge treatment process extends tool life by eliminating microscopic imperfections in the cutting edges

OPEN FLUTE STRUCTURE

- Engineered flute shape efficiently transports chip volume without sacrificing strength

- Puts coolant as close to cut as possible for consistent chip flushing, maximum cooling, and highest productivity

Coating

High wear resistance, reduced friction, and excellent prevention of cutting edge build up. This coating allows superior material removal rates and tool life when used in high performance operations in Cast Iron and Steel and with difficult to machine materials like Titanium.

Series Details

Lineup Details

- Cutting Diameter: 1/8"-3/4" | 3,0 mm - 19,05 mm

- Length of Cut: 23,0 mm - 72,0 mm

- Overall Length: 66,0 mm - 153,0 mm

- Flute Length: 28,0 mm - 101,0 mm

- Shank Diameter: 6,0 mm - 20,0 mm

- Coating: Ti-NAMITE®-M

Primary Material Applications

- Cast Iron ≤ 45 HRc

- Cast lron ≥ 45HRc

Industry Applications

Automotive

Mold & Die

Casting & Foundries

General Engineering

Secondary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- High Temp Alloys

- Titanium Alloy ≤ 45 HRc

- Non-Ferrous

- Plastics / Composites

- Hardened Steels < 45 HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.