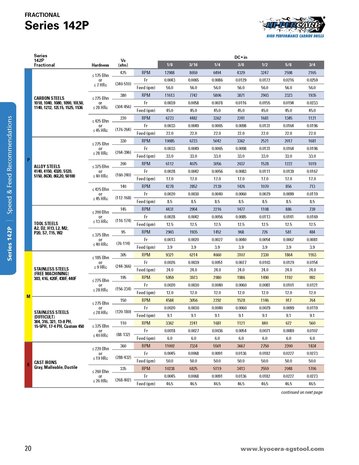

HIGH

PRODUCTION

STEEL HOLEMAKING

Hi-PerCarb® | Series 142P

This innovative design enhances hole straightness and roundness, ensuring exceptional stability in challenging scenarios such as cross holes and angled exits. Additionally, Hi-PerCarb® Series 142P features a coolant-through design that optimizes coolant flow, extending tool life and facilitating efficient chip evacuation for seamless operations.

Features

HIGH PERFORMANCE 4-MARGIN DESIGN

- Stabilizes on entry for exceptional hole size allowing for low thrust force and extended tool life

- 4-margin design improves hole straightness and roundness while providing improved stability for difficult applications like cross holes and when exiting on angle

COOLANT THROUGH DESIGN

- Improves coolant flow to extend tool life and aid in chip evacuation

Coating

Suitable for operations which require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates. From high- and low- alloy steels to hardened materials (up to 65 HRC core hardness), the design is adapted to meet a diverse range of applications

Series Details

Lineup Details

- Cutting Diameter: 1/8" - 3/4" | 3,0 mm - 19,05 mm

- Length of Cut: 15,0 mm - 238,0 mm

- Overall Length: 62,0 mm - 319,0 mm

- Flute Length: 20,0 mm - 266,0 mm

- Shank Diameter: 6,0 mm - 20,0 mm

- Coating: Ti-NAMITE®-X

Primary Material Applications

- Steel ≤ 45 HRc

- Copper Alloys

- Titanium Alloys ≤ 45 HRc

- High Carbon, Medium Alloys

Industry Applications

General Engineering

Casting & Foundries

Mold & Die

Automotive

Power Generation

Medical

Aerospace

Firearms

Secondary Material Applications

- Stainless Steel ≤ 45HRc

- Cast Iron ≥ 45 HRc

- Alluminum Alloys

- Titanium Alloys ≤ 45 HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.