MAXIMIZING TOOL LIFE

12 Strategies and Factors for Tool Longevity

Premature tool wear is a common and challenging issue faced by machinists. Tool wear refers to the gradual deterioration of cutting tools caused by the forces and conditions experienced during cutting. This wear can lead to reduced accuracy, diminished surface finish quality, increased production time, and higher costs due to frequent tool replacements.

Below are 12 factors you should consider to help increase the longevity of your tools. Contact your local SGS Field Sales Engineer to discuss which of these strategies you should apply to your specific machining applications.

12

Strategies and Factors

1.

Cutting speed directly affects tool wear. Operating at excessively high speeds generates excessive heat, leading to quick wear. Running at very low speeds results in inefficient cutting and accelerated wear. Finding the optimal cutting speed for a specific operation is crucial for prolonging tool life.

2.

Feed Rate: The distance a cutting tool advances into the workpiece per revolution, known as the feed rate, significantly affects tool wear. Incorrect feed rates, whether too high or too low, can lead to excessive wear. High feed rates cause chipping and breakage, while low feed rates result in rubbing and increased friction. Machinists must optimize the feed rate to strike a balance that minimizes wear and maximizes productivity.

3.

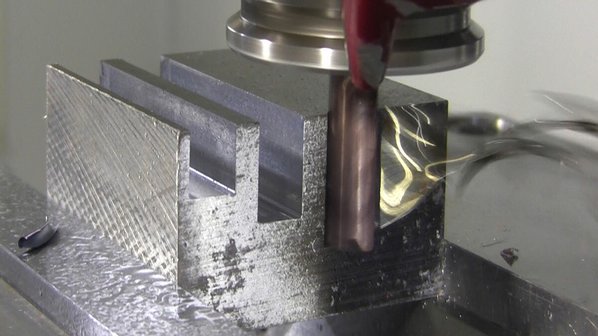

Chip evacuation: Proper chip evacuation is essential for extending tool life. Inadequate chip evacuation may lead to recutting work-hardened chips, which would damage the tool. It can also cause chip packing, reducing chip space and increasing cutting forces, which may result in tool breakage. Optimizing cutting parameters, tool geometry, and coolant/lubrication techniques ensures effective chip evacuation, minimizing wear and improving productivity.

Z-Carb HPR High Performance Rougher

4.

Tool Material: The material being machined plays a critical role in wear. Harder materials tend to cause faster wear, necessitating robust and wear-resistant tooling. Carbide tooling, with a cemented carbide substrate, is a highly reliable option for precision machining. SGS offers tested and quality-controlled carbide substrates for superior performance and longevity.

5.

Geometry: Apart from the substrate, the cutting geometry of the tool is crucial for efficient cutting performance. SGS's precision tooling is meticulously engineered with cutting-edge designs to enhance performance, productivity, and tool life. Be sure to browse the various options optimized for different materials and operations. Check out SGS's Tooling Matrix for a quick look at how these tools stack up against materials and applications.

6.

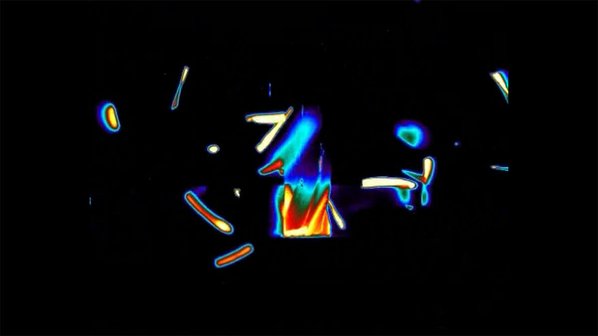

Tool Coatings: The application of coatings on precision tools provides additional advantages. SGS's tool coatings are designed to maximize tool life and boost productivity. These coatings offer benefits like enhanced resistance to abrasive wear, increased resistance to oxidation, effective thermal barriers, reduced adhesion, and enhanced lubricity. All of these additional benefits will help extend the tool’s life.

Thermal Image of uncoated tool heating up in 4140

7.

Coolant / Lubrication: Effective coolant and lubrication minimize wear by reducing friction and heat buildup. Inadequate or improper coolant and lubrication can contribute to increased friction and wear on the cutting edges. This can lead to heat buildup and accelerating tool wear. To combat this, machinists need to implement proper cooling and lubrication techniques, such as using the appropriate type and concentration of coolant and lubricant. Using the appropriate type and concentration of coolant and lubricant is crucial. For flood coolant applications, distributing flow between the tip of the cutting edge and the top of the flutes ensures optimal tool life.

8.

Tool Path: The chosen tool path affects tool life due to factors like cutting forces, chip formation, chip evacuation, heat generation, and tool engagement. Trochoidal tool paths, while not a solution for every application, do tend to extend tool life due to their ease in and out of the material and consistent engagement angle. Optimizing the tool path for the selected tool and application minimizes wear and extends tool life.

9.

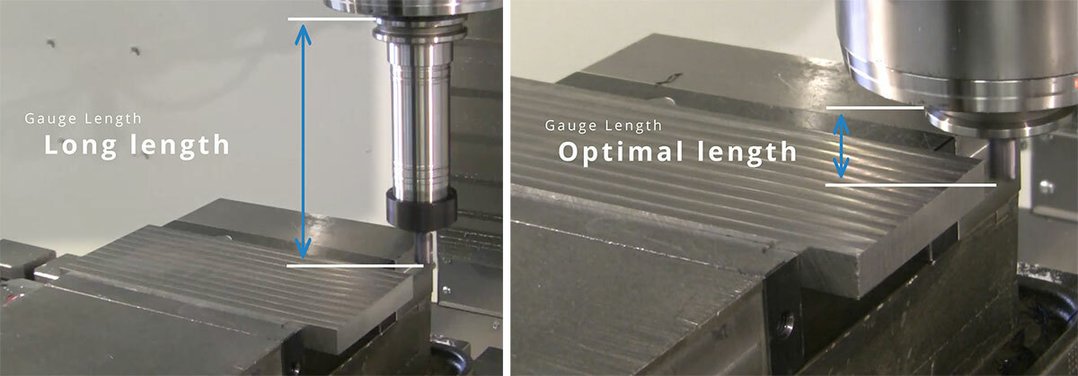

Gauge length is the distance between the end of the tool and the tool holder. This length has a direct impact on tool life. Longer lengths cause deflection, vibration, and concentrated cutting forces, accelerating wear and in extreme cases tool breakage. Minimizing gauge length enhances tool rigidity, reduces deflection and vibration, and evenly distributes cutting forces, extending tool life.

10.

Fixturing: A well-designed fixture provides stability, reduces vibrations, and ensures accurate workpiece positioning. Poorly designed fixtures result in excessive vibration and movement, increasing wear. Implementing a proper fixture strategy significantly reduces wear, improves cutting performance, and extends tool life.

11.

Tool Holder: The tool holder is the direct connection between the tool and the machine, and it plays a critical role in securely holding the cutting tool in place and providing stability during machining. It affects tool life by influencing factors such as tool runout, tool deflection, and vibration damping. An appropriately designed and rigid tool holder minimizes runout and deflection, ensuring accurate cutting and reducing the risk of premature tool failure. Additionally, a well-designed tool holder can effectively dampen vibrations generated during cutting, preventing tool chatter, and extending tool life. Therefore, selecting a high-quality and appropriate tool holder that provides excellent rigidity, precision, and vibration-damping capabilities is essential for maximizing tool life in machining operations.

12.

Machine condition significantly impacts tool life in machining operations. A well-maintained and calibrated machine ensures stable cutting conditions, minimizing vibrations and deflection that cause premature tool wear. Conversely, a machine in poor condition introduces excessive vibration, tool chatter, and inaccurate positioning, increasing forces on the cutting tool. These unfavorable conditions accelerate tool wear, compromise accuracy, and reduce surface finish quality. Regular machine inspections, maintenance, and alignment checks are vital for optimizing machine conditions and extending tool life.

By implementing these strategies and using high-quality precision tools offered by SGS, machinists can combat premature wear, maximize tool life, and optimize productivity. SGS's precision tooling, coatings, and optimized options for different materials and operations ensure reliable and long-lasting tools. Don't let premature wear hold you back—choose SGS for superior machining results. Contact your local sales engineer today to experience the benefits of SGS's tools, coatings, and full-scale machining solutions.

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.