HIGH-SPEED

CONTOUR

MILLING

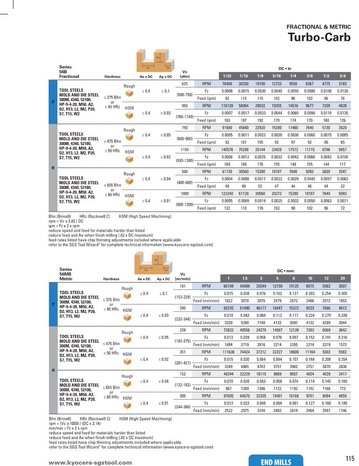

Turbo-Carb | Series 56

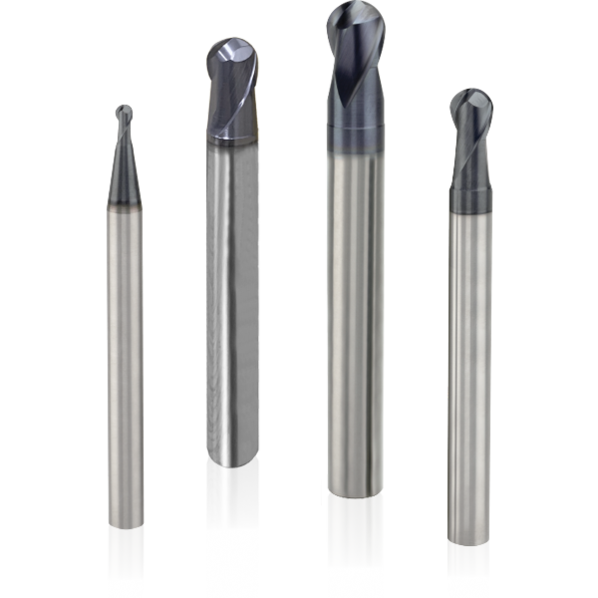

Designed for high-speed roughing and finishing of complex contoured shapes in hardened materials. The Turbo Carb end mill is made of an application-specific carbide to improve wear resistance and toughness in demanding applications. The high-performance S-Gash geometry on the ball improves shearing while reducing the load. With the exclusive Ti-NAMITE-X tool coating, these tools are ideal for dry machining.

Features

Flute

- Short flute length and a rigid design to reduce deflection.

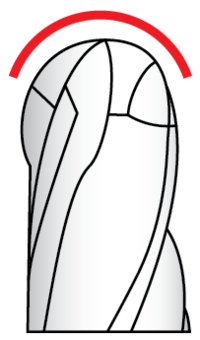

End Geometry

- S-Gash Ball geometry minimizes load and heat produced during the cutting process, ultimately enhancing tool life.

Machining

- Ideal for machining complex contoured shapes in hardened steels.

- The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low-alloy steels to hardened materials (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations which require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates.

Series Details

Lineup Details

- Cutting Diameter: 1/32"-3/4" | 1,0 mm - 20,0 mm

- Length of Cut: 1/32"-3/4 | 1,0 mm - 20,0 mm

- Overall Length: 3"-6 1/2" | 76,0 mm - 165,0 mm

- Shank Diameter: 1/4"-3/4" | 6,0 mm - 20,0 mm

- Reach: 1/16"-1 1/2" | 2,0 mm - 40,0 mm

- Coating: Ti-NAMITE-X

Primary Material Applications

- Cast Iron ≥ 45 HRc

- Hardened Steel < 45 HRc

- Hardened Steel > 55 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Secondary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

- Non-Ferrous

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.