MAXIMUM

PERFORMANCE

Milling

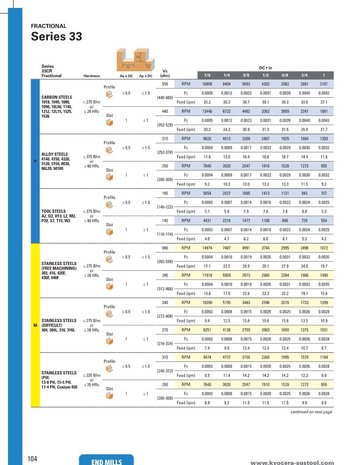

Series 33

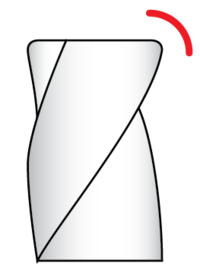

Series 33 end mills use the latest in engineering design and grinding capabilities. They are ideal for aggressive ramping, pocketing, and slotting in difficult to machine materials such as Stainless Steel, Titanium, and Inconel. Designed for applications challenged by heavy chip evacuation, this 3-flute design offers increased chip clearance and a reduction in harmful harmonics.

Features

Flute

- Proprietary 3-flute design allows for more controlled chip formation and efficient chip evacuation.

Design

- The specially engineered stepped core design provides stability for aggressive ramping and rigidity when flutes are entirely engaged.

- Open design at the axial end accommodates material flow and load reduction during operations.

Corner Geometry

- Enhanced corner geometry with tight tolerance corner radii.

- Available with Ti-NAMITE®-A coating for superior wear, edge build-up resistance and extended tool life in difficult-to-machine materials like Stainless Steel.

Series Details

Lineup Details

- Cutting Diameter: 1/8"-1" | 3,0 mm - 20,0 mm

- Length of Cut: 3/8"-2 1/4" | 9,0 mm - 46,0 mm

- Shank Diameter: 1/4"-1" | 6,0 mm - 20,0 mm

- Corner Radius: .015-.040 | 0,3 mm - 4,0 mm

- Coating(s): Ti-NAMITE-A (AlTiN)

Primary Material Applications

- Stainless Steel ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Secondary Material Applications

- Steel ≤ 45 HRc

- Cast Iron ≤ 45HRc

- Cast Iron ≥ 45 HRc

- Hardened Steel < 45 HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.