MAXIMUM

ROUGHING

EFFICIENCY

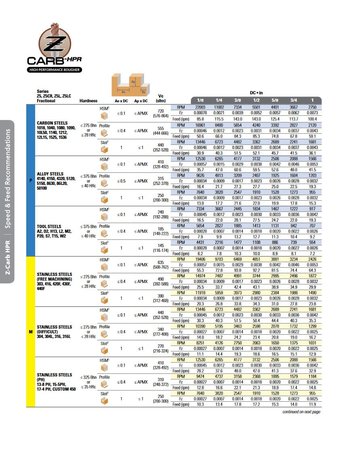

Z-Carb HPR | Series Z5

The Z-Carb HPR Five Flute Roughing End Mills are ideal for achieving high metal removal rates (MRR) and a finish of 80 RMS or better on most materials. The specialized five flute design is engineered for increased productivity over three and four flute end mills. The variable indexing geometry allows for improved chatter suppression over symmetrical designs.

Features

Radial Rake

- Specially designed radial rake balances positive cutting action and edge strength.

- End grind features include a positive axial rake for high-performance shearing and lifting of material and increased clearances to eliminate edge build-up during ramping.

- The central hole delivers coolant effectively to the cutting zone.

- Enhances chip removal when pocketing or slotting.

- Select fractional and metric diameters in stock.

- Specialized five-flute design is engineered for strength, chip evacuation, and increased productivity over three and four-flute end mills by 20–40%.

- The variable flute pattern provides excellent chatter suppression over a range of spindle speeds.

- The open-center design delivers efficiency during entry movements into the workpiece.

- Helix angle engineered for balance between positive cutting action and reduced contact area to control tool pressure and spindle load.

Ti-NAMITE-M - Higher heat resistance to enhance tool life in difficult-to-machine materials like Titanium

Ti-NAMITE-A - Superior wear, edge build-up resistance and extended tool life in difficult-to-machine materials like Stainless Steel

NEW MEGACOAT NANO - Nano-layers of this coating provide high hardness for exceptional wear resistance and high oxidation resistance that allows for operation at high temperatures. The layered structure also gives the coating the toughness required to resist chipping.

Series Details

Lineup Details

- Cutting Diameter: 1/8" - 1" | 6,0mm - 25,0mm

- Length of Cut: 1/4" - 2" | 9 mm - 53,0 mm

- Overall Length: 1 1/2" - 4 1/2" | 54,0 mm - 121,0 mm

- Shank Diameter: 1/8" - 1" | 6,0mm - 25,0mm

- Corner Radius: 0.010" - 0.250" | 0,3mm - 5,0mm

- Coating(s): Ti-NAMITE-M, Ti-NAMITE-A, MEGACOAT NANO

- Special Options: Internal Coolant, Weldon Flat, Chip Breaker

Primary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Firearms

Secondary Material Applications

- Cast Iron ≥ 45 HRc

- Hardened Steels < 45 HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.